Design – Manufacture – Test

With over 55 years of experience, cutting-edge facilities and unparalleled expertise, we are more than partners in aerospace innovation; we are fellow engineers.

Our Capabilities

With over 55 years of trust in the aerospace industry, we are a family-run company that excels in design, manufacture and testing of aerospace products. As a fully vertically integrated organisation, certified to ISO 9001 and EN9100, we have a strong foundation of significant investments in expanding our capabilities. Our cutting-edge facilities and skilled workforce across multiple disciplines enable us to go beyond mere collaboration; we become your fellow engineers, working alongside you from concept to qualification.

Our Process

Our vertically integrated facilities and streamlined processes enable seamless collaboration across the engineering, manufacturing and testing teams. Our in-house testing expedites communication and problem-solving, enabling us to deliver exceptional products more efficiently.

DesignMulti-Disciplinary Teams

Mechanical Engineering

- Design and develop – We can create innovative CAD designs, assess feasibility, develop detailed drawings, select appropriate materials and collaborate with you to bring concepts to reality.

- Analyse and resolve mechanical problems – Our team can diagnose, analyse, investigate and implement preventive measures to ensure equipment safety and efficiency.

- Perform experiments to test and improve – Conducting experiments to collect data on the performance, identify areas for improvement and develop new and innovative designs.

- Create and manage manufacturing processes – our engineers use their knowledge of engineering principles, materials science and manufacturing techniques to develop efficient and cost-effective ways to produce mechanical components and assemblies.

RF Engineering

- Design and develop – Our RF engineers design and develop a wide variety of RF systems and components, including antennas, filters, amplifiers, and transmitters and receivers. They use their knowledge of electromagnetic theory, circuit theory and signal processing to create devices that are efficient, reliable and meet the specific requirements of aerospace applications.

- Optimize RF signals for transmission and reception – Our engineers use their knowledge of RF propagation and antenna theory to design and implement efficient RF communication systems.

- Develop RF test equipment and methodologies – Using their knowledge of RF theory and measurement techniques to design and build test equipment that can be used to measure and characterise the performance of RF devices and systems.

- Work with other engineers, technicians, and scientists to solve complex RF challenges – We believe that this collaboration is essential for developing innovative RF solutions with you.

Electrical Engineering

- Design and develop – Our team can create analogue circuits and PCBs for a wide range of applications, from audio amplifiers to solid state power supplies to battery charging circuits.

- Analyse and evaluate electrical performance – Using their knowledge of electrical theory and measurement techniques to measure and characterise the performance of devices, identify areas for improvement and ensure that systems meet the required performance specifications.

- Develop electrical test equipment and methodologies – Our engineers utilise electrical theory, measurement techniques, and CAD to design and build test equipment that can be used to measure and characterise the performance of electrical devices and systems.

- Work with other engineers, technicians, and scientists to solve complex electrical challenges – We believe that this collaboration is essential for developing innovative electrical solutions with you.

Software Engineering

- Design and develop – Our team can develop software programs to control emergency transmitting equipment and intelligent antenna systems.

- Testing software – Ensuring that it is free of bugs and meets the requirements of the project.

- Keep up with the latest software technologies – The software industry is constantly evolving and our software engineers are able to keep up with the latest technologies.

- Modelling & Simulation – Our team brings your ideas to life through advanced concept development software. Collaboratively, we not only visualise your ideas but also subject them to rigorous simulations for testing and refinement.

ManufactureRaw Materials to End Product

We understand the importance of attention to detail, which is why we only purchase a select few components. The majority of our products are crafted in-house, starting from raw materials. This encompasses radomes, connectors, PCBs, and we even create the tooling for the moulds.

Mould & Tool Shop – We are a fully equipped facility with a wide range of manufacturing capabilities, including CNC milling machines, injection moulding machines, hydraulic presses, lathes, and custom tool & jig production.

Production Line – Our state-of-the-art production process incorporates rigorous testing and feedback mechanisms, skilled hand assembly stations, automated pick-and-place PCB machines, meticulous X-ray PCB scanning, precision painting, comprehensive quality control test areas, and a dedicated logistic team to ensure the highest quality and efficiency.

TestTesting & Quality Assurance

- Our investment in in-house testing ensures that we are fully equipped to perform comprehensive environmental and mechanical testing to aviation standards MIL-STD-810 and DO-160G.

- Our in-house testing reduces turnaround times, enabling quicker product assessments and faster iterations.

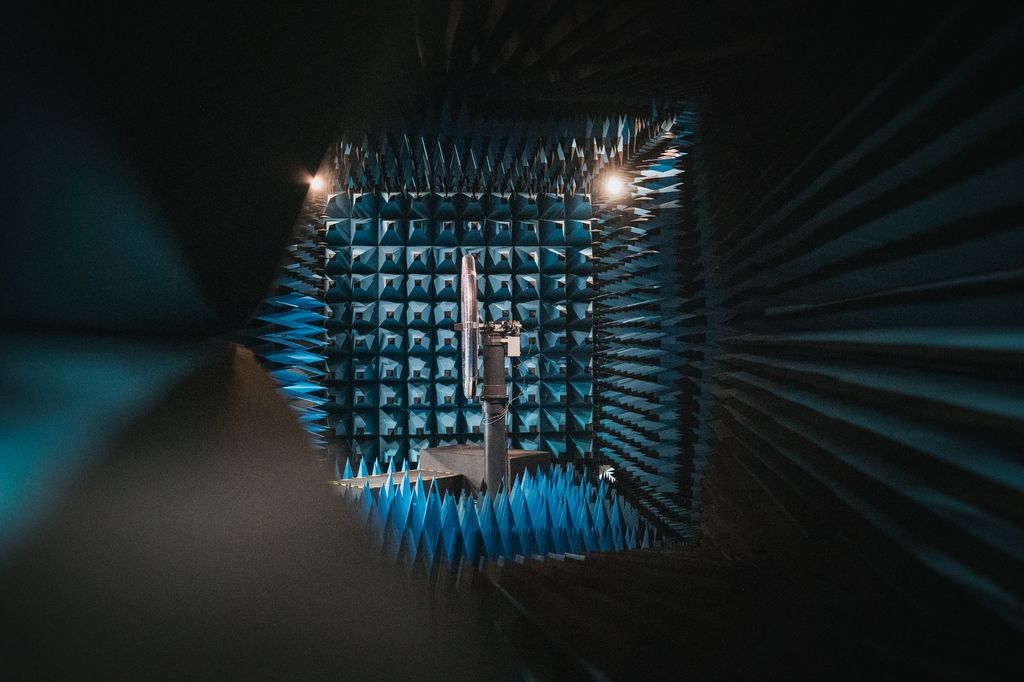

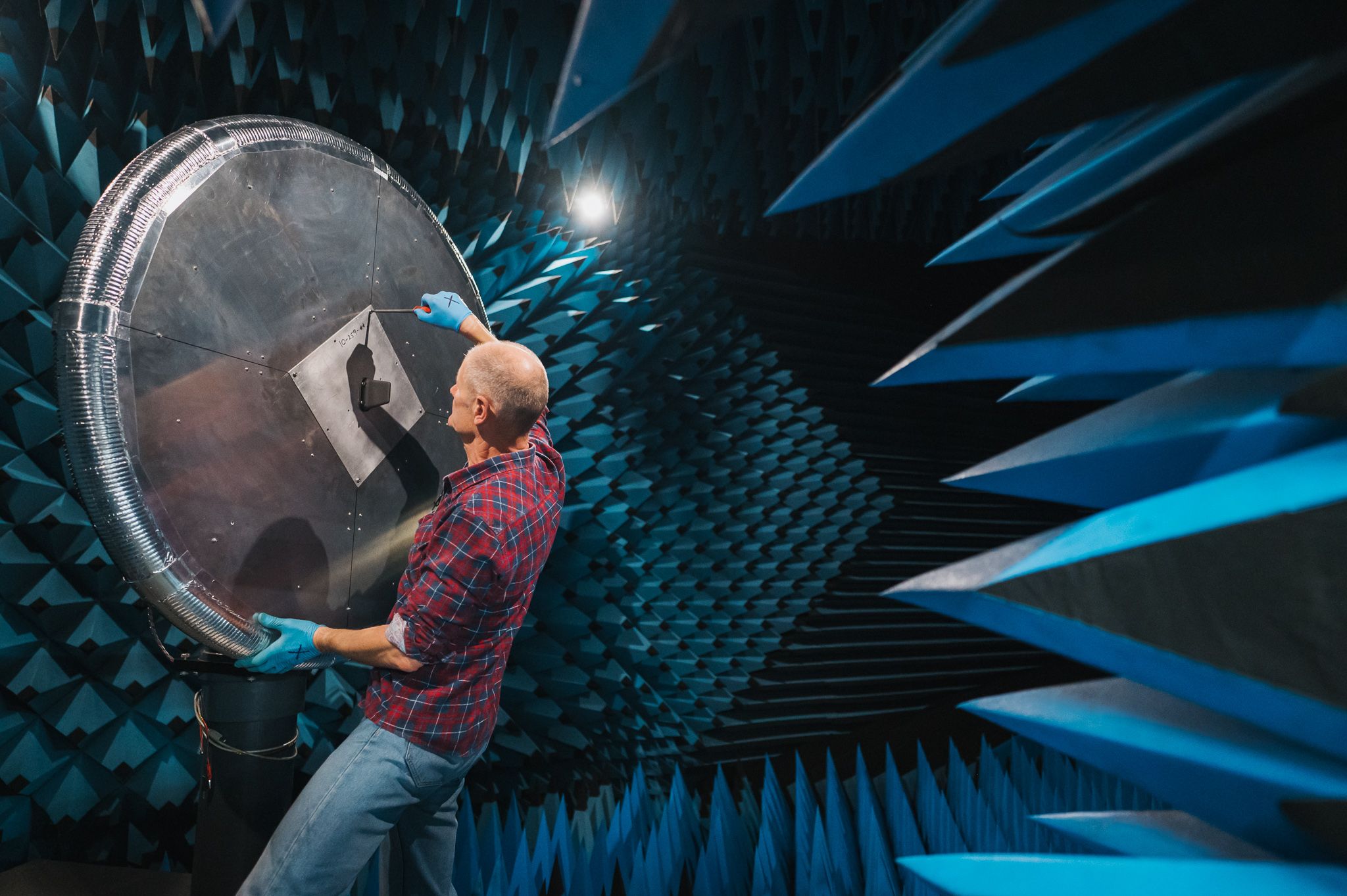

- Anechoic chambers

- EMC chamber

- Outdoor antenna test area

- Vibration tables

- Drop, impact and penetration jigs

- Centrifuge

- Tensile testing

- Temperature chambers

- Solar radiation

- Salt and fog chambers

- Outdoor antenna test range

- Flame and Fire testing

- Immersion

- Lithium battery testing

Our Approvals & Certifications

- ISO 9001 Accredited

- AS EN 9100 Accredited

- FAA Approved

- CAA Part 21G Approved

- CAA Part 145 Approved

- EASA Part 145 Approved

- CAA ADOA Approved

- UK MoD DAOS Approved

- Cyber Essentials Plus Accredited

- JOSCAR Accredited

- Cospas Sarsat (Type approved products)

- UK TSO, ETSO & TSO (Product approvals)

Want To Know More?

Ready to take your aviation experience to new heights? Interested in learning more about our innovative solutions? Whether you’re seeking detailed information or a comprehensive brochure, our team is here to assist you. Contact us today to explore the possibilities and embark on a journey towards safer, smarter aviation